Pressure booster

-

Product is not available

Country Of Origin : India

Pressure booster DPA

Characteristics

At a glance

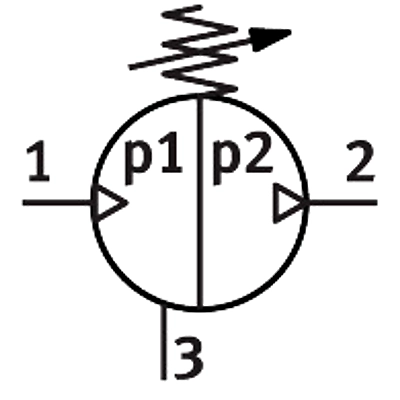

The pressure booster is a twin-piston pressure intensifier used only for compressing air. When the DPA is pressurised with compressed air, integrated check valves automatically ensure the pressure on the secondary side is built up. The output pressure p2 can increase to up to twice the value of the input pressure p1. The required output pressure is set using a manually operated pressure regulator. In the case of pressure boosters without a pressure regulator, the output pressure is always double the input pressure. The air supply to both drive pistons is controlled by a pneumatic directional control valve that reverses automatically when the stroke end position has been reached. The pressure booster starts up automatically when the input pressure is applied and the desired output pressure has not yet been reached. When the set output pressure is reached, the pressure booster stops operating to save energy, but restarts automatically when the output pressure drops again.

•

Available as pressure booster/air pressure reservoir combinations

•

Long service life

•

Compact design

•

Available with sensing option

Note: Pressure boosters are used for the occasional drawing-off of pressurised compressed air. Pressure boosters are not suitable as a substitute for a compressor, as wear on the seals and drive piston increases significantly when used continuously without breaks.

Note: A pressure gauge is strongly recommended to check the output pressure p2, as the required output pressure p2 must be set. The regulator setting of the DPA-63/100 can be secured against unauthorised adjustment using the regulator lock LRVS.